H2Pioneer

Pave the way for green hydrogen for early adopters in the light industry

Project description

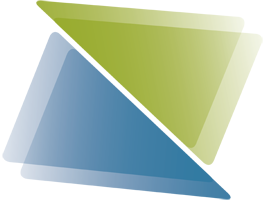

At Infineon Austria AG, Villach hydrogen is used in the semiconductor production process, as a carrier gas for silicium precursors such as trichlorsilane for the deposition of epitactical layers. After layer deposition, hydrogen emitted highly diluted into the atmosphere. Strict requirements on the purity of the hydrogen (8.0 or 99,999999 Vol%) and at the same time large demands are extremely challenging in terms of quality management, procurement and reliable logistics. The present situation of hydrogen supply is the delivery of liquefied hydrogen, produced from fossil resources, by fuel trucks from Leuna (Germany) or Rozenburg (Netherlands), two of only three sources of liquefied hydrogen supply in Europe. Since growing production capacities are expected due to the introduction of new products and technologies to the market in the next years, a significant increase in demand for highly pure hydrogen at IFAT is expected. Therefore, the current supply concept reaches its capacity limit and alternatives are evaluated.

The overarching goal of H2Pioneer is to establish an onsite-production of hydrogen to meet the expected increasing demand of the semiconductor industry. Hydrogen will be produced round the clock (7/24) in highest quality according to the economic and ecological requirements of „green industry“. The first innovation is the implementation of the onsite PEM electrolysis plant and the purification process to ensure 8.0 quality of hydrogen. The second substantial innovation is the conception and evaluation of reutilization strategies of the exhaust hydrogen, at present disposed of as waste, within a “green hydrogen cycle” (recycling, back to process or energetic use).

Project goals

Expected Results and Findings: Within the project H2Pioneer, an onsite PEM electrolysis plant, operated with renewable electricity, is demonstrated at Infineon, Villach. The highest purity of hydrogen has to ensured and its supply reliability has to be increased. A system concept for the reutilization of the exhaust hydrogen is developed. Reutilization of the hydrogen, which is released into the environment at present, considers recycling back to the EPI process as well as energetic reuse. This substantially contributes to the efficiency increase of hydrogen production and usage and to the establishment of “green industry” and sector coupling in accordance with the goals defined in WIVA P&G.

Factsheet

Contribution of partners

- VERBUND Energy4Business GmbH

coordinates the project and contributes with comprehensive energy know-how as well as with experience in implementation in terms of PEM-elektrolyzers. - Infineon Technologies Austria AG

is implementation partner and works on the systen integration of the hydrogen supply through PEM-elektrolyzer. - HyCentA Research GmbH

researches the implementation of the demonstration plant in the project as well as the potential reprocessing of hydrogen used in the semiconductor industry. - Energieinstitut an der JKU Linz

is responsible for the accompaniying scientific analysis on a macroeconomic level as well as for rollout-scenarios in similar industrial processes. - WIVA P&G

is responsible for the scientific supervision and monitoring. - Linde GmbH

constuction, building and operation of the first plant for on-location production of green hydrogen in the Austrian semiconductor industry.

Project videos

Galery

Project News

H2Pioneer: Vortrag NEFI Konferenz – Martin Sagmeister

Auf der NEFI Konferenz 2022 in Linz wurde von Martin Sagmeister (HyCentA) ein Vortrag mit dem Titel

„RECYCLING AND SECOND USE OF GREEN HYDROGEN FROM SEMICONDUCTOR INDUSTRY” gehalten.

Der Beitrag entstand durch Forschungsarbeiten im Projekt H2Pioneer.

H2Pioneer – Wiederverwertungsmethoden für Wasserstoff in der Halbleiterindustrie

Im Zuge des 16. Symposium Energieinnovation 2020 von 12.-14.02.2020 mit dem Thema „ENERGY FOR FUTURE – Wege zur...

Presseinformation – Österreichisches Forschungsprojekt „H2Pioneer“ Grüner Wasserstoff für die Halbleiterindustrie

18. August 2021 - Das Halbleiterunternehmen Infineon Technologies Austria und das Industriegase- und...